- 22 October 2014

- Posted by: nemcatgroup

- Category: Publications

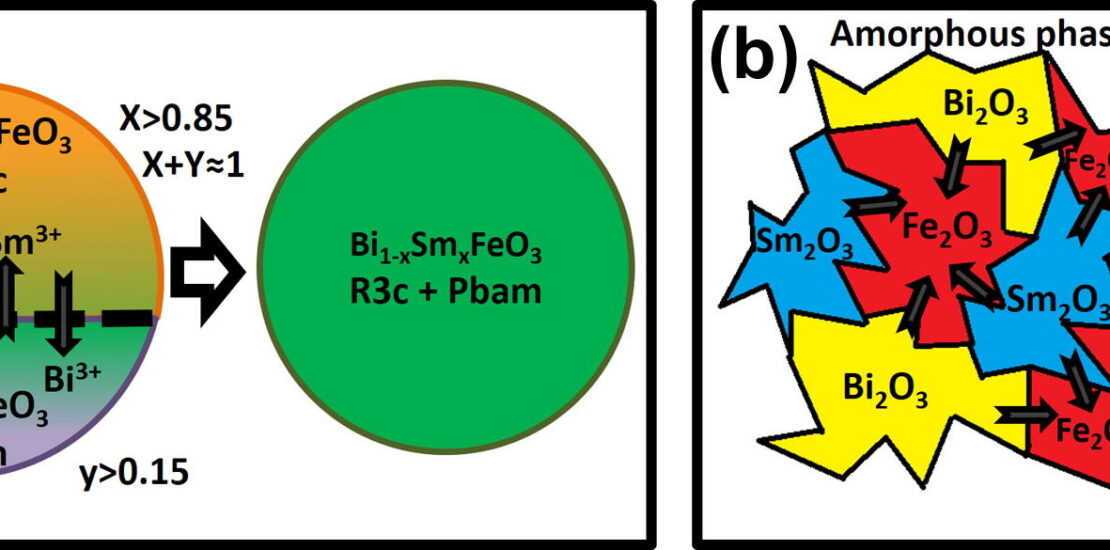

Solid-state (non-activated) and mechanochemical activation (activated) synthesis methods were used to produce Sm-modified BiFeO3 ceramics of composition Bi0.88Sm0.12FeO3. The first part shows that the formation of Bi0.88Sm0.12FeO3 using the two synthesis methods followed a different reaction pathway on annealing the powders. The non-activated ceramics reacted by forming two intermediate phases, isostructural to BiFeO3 and SmFeO3, and then inter-diffusing, forming the final Bi0.88Sm0.12FeO3 solid solution. Unlike the non-activated samples, the activated ceramic powders formed Bi0.88Sm0.12FeO3 phase on annealing the powders, without apparent intermediate phases. As revealed by transmission electron microscopy, the non-activated reaction pathway caused the Pbam phase to form as chemical inhomogeneous (Sm-rich) isolated nano-sized grain inclusions in the final ceramics. Conversely, the activated reaction pathway caused the Pbam phase to form chemically homogeneous nano-regions within the R3c phase grains. The results demonstrate the important role of processing in the appearance of the frequently discussed anti-polar Pbam phase in this system. In the second part, the high electric-field-induced polarization and strain behaviors of these ceramics were studied by means of polarization–electric (P–E) and strain–electric field (S–E) hysteresis loops, and the S–E loops were compared with those of unmodified BiFeO3. Bipolar S–E loops of Bi0.88Sm0.12FeO3 had a distinctive butterfly shape with less frequency dependence relative to BiFeO3 at driving-field frequencies of 0.1–100 Hz. BiFeO3 ceramics exhibite strong driving electric-field-frequency-dependent domain switching, the origins of which were previously attributed to a domain-wall pinning mechanism and “hardening” behavior. This study shows that Sm-modification induces a “hardening–softening” transition in BiFeO3 ceramics.