- 11 May 2010

- Posted by: nemcatgroup

- Category: Publications

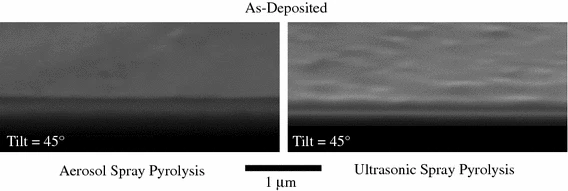

The present work presents a comprehensive model of both processes and outcomes of the spray pyrolysis mechanism, which is based on wide-ranging experience gained from experimentation involving a range of parameters. The deposition temperature and initial droplet size are the main parameters controlling film properties, including mineralogy, surface morphology, thickness, and bonding; the effect of annealing on these properties also is considered. The model is supported experimentally through the processing of films aerosol and ultrasonically spray pyrolyzed at 350°C, followed by annealing for 12 h at 500°C in air. Assessment of the mineralogy, chemical bonding, and crystallinity/residual stress of the films involved glancing-angle X-ray diffraction and laser Raman microspectroscopy, Fourier transform infrared spectroscopy, and crossed polarizers with an optical microscope, respectively.