- 1 February 2024

- Posted by: nemcatgroup

- Category: Publications

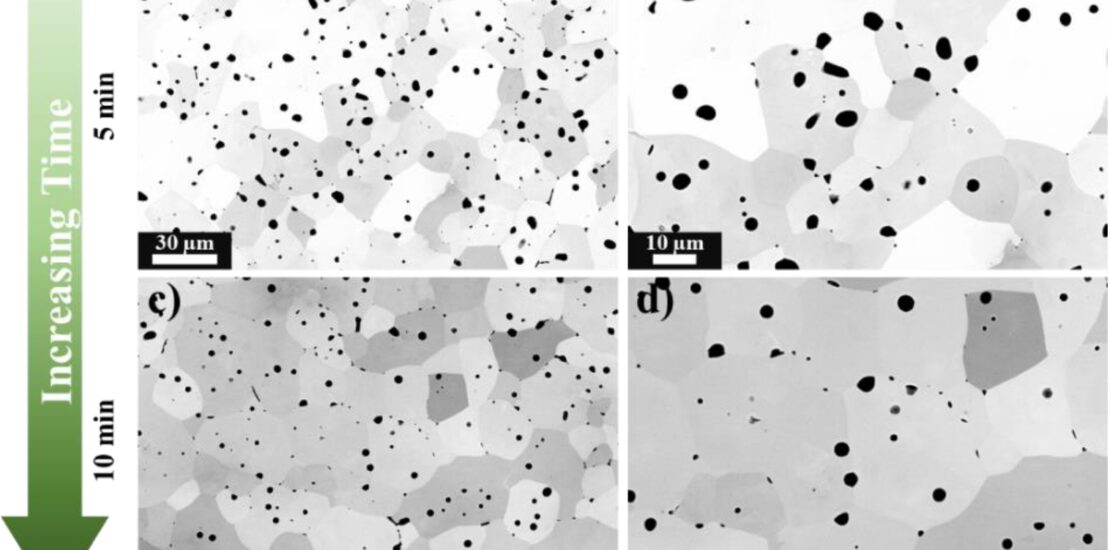

Zirconium diboride (ZrB2), an ultra-high temperature ceramic (UHTC) is characterised by its combination of metallic and covalent bonding which confers high strength and a high melting temperature (>2500degreesC). These thermo-physical-mechanical properties coupled with the strong covalent bonding and low intrinsic self-diffusivity result in excellent high-temperature performance suitable for various energy, space, and defence applications; however, owing to these characteristics, UHTCs typically require elevated temperatures and pressures for consolidation. This work investigates the effect of consolidation temperature and dwell time on the microstructural development and density of zirconium diboride (ZrB2) fabricated via spark-plasma sintering (SPS). It was observed that increasing consolidation temperatures resulted in higher bulk densities (72.2% (1900degreesC), 95.2% (1950degreesC), 96.4% (1980degreesC), and 97.1% (2000degreesC)). Poor densification at 1900degreesC was attributed to insufficient thermal energy limiting gain boundary and lattice diffusion and grain boundary sliding whilst beyond 1950degreesC, density appeared to stabilise accompanied by residual intragranular porosity arising from grain coarsening. Extended dwell times at a lower temperature (1900degreesC), resulted in increased density, but substantial residual apparent porosity was measured (16-20%) for dwell times of 5 min, 10 min, and 20 min. At a higher temperature (1950degreesC), this effect diminished with modest (<0.5%) density increases for longer dwell times. Elevated temperatures had a more pronounced effect on densification compared to extended dwell times due to the former’s impact on enhancing diffusion mechanisms.