- 10 February 2012

- Posted by: nemcatgroup

- Category: Publications

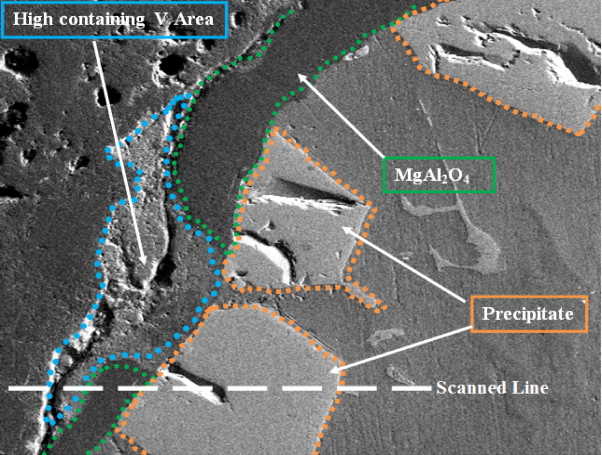

Interfacial reactions between Al-alloy and andalusite low-cement castables (LCC) containing 5 wt% V2O5 were analyzed at 850 °C and 1160 °C using the Alcoa cup test. Interfacial reaction products and phases formed during heat treatment of the refractory samples were characterized using scanning electron microscopy (SEM) coupled with energy dispersive spectrometry (EDS) and X-ray diffraction (XRD) analysis. V2O5 addition resulted in the formation of glassy phases, which significantly improved the corrosion resistance. These phases were preferentially corroded by the alloy, due to their glassy nature. However, vanadium formed from reduction, formed intermetallic alloys (V–Al–Si–Mg), which formed an interfacial physical barrier to further alloy penetration.