- 14 December 2023

- Posted by: nemcatgroup

- Category: Publications

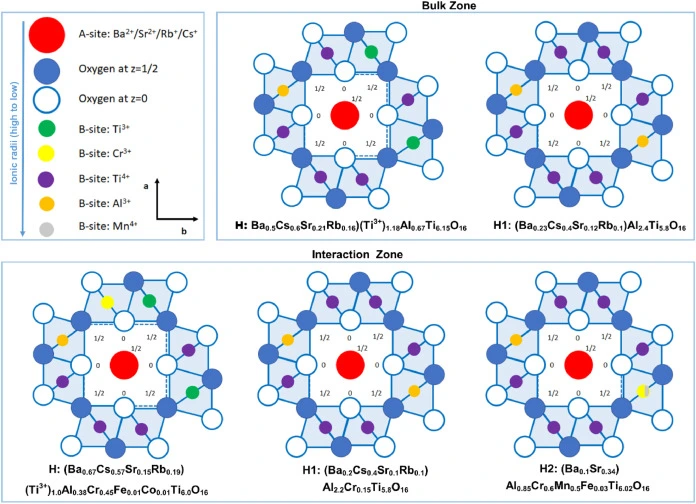

A potential hollandite wasteform for immobilising waste containing Cs, Ba, Sr, and Rb, projected from a solvent extraction process that separates Cs/Sr from spent nuclear fuel, was fabricated via hot isostatic pressing (HIPing) within a stainless-steel (SS) canister at 1250 °C / 30 MPa / 2 h. Before HIPing, 2 wt.% Ti metal was added to the precursor, as a redox control additive. Detailed elemental profiling and microstructural analysis at the interaction zone between the wasteform and the SS HIP canister were thoroughly investigated with transmission electron microscopy (TEM) using a lamella extracted by focused ion beam (FIB) milling, scanning electron microscopy (SEM) and X-ray diffraction (XRD). The interaction zone towards the wasteform was ∼20–30 µm in distance and in this region, a hollandite composition with varying chemistry was observed relative to the bulk wasteform. Moreover, the regular Cr-oxide layer, often observed previously for HIPed Synroc-type materials, was not present due to the achievement of reducing condition by adding Ti-metal as redox additive and simultaneous diffusion of canister material towards the ceramic. Predominant Cr-diffusion was observed with incorporation in the hollandite phase along with minor Fe, Mn and Co from the SS canister. This study provides a detailed understanding of the HIP canister – wasteform interaction zone for a hollandite-rich wasteform design for the first time. Importantly, no deleterious phases were formed that may otherwise reduce the performance of the wasteform. This study further demonstrates the flexibility of HIPing as a consolidation process for the treatment of radioactive wastes.