- 21 December 2011

- Posted by: nemcatgroup

- Category: Publications

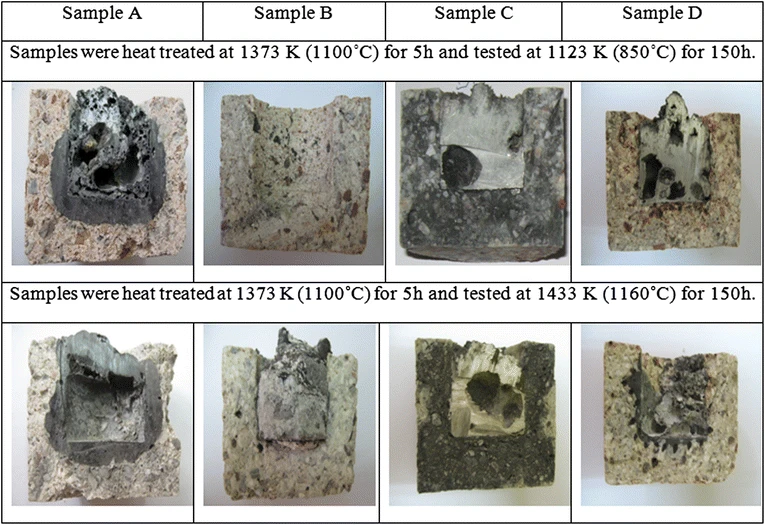

Interfacial reactions between Al alloy and andalusite low-cement castables (LCCs) containing 5 wt pct B2O3, B4C, and BN were analyzed at 1123 K and 1433 K (850 °C and 1160 °C) using the Alcoa cup test. The results showed that the addition of boron-containing materials led to the formation of aluminoborate (9Al2O3.2B2O3) and glassy phase containing boron in the prefiring temperature (1373 K [1100 °C]), which consequently improved the corrosion resistance of the refractories. The high heat of formation of the aluminoborate phase (which increased its stability to reactions with molten Al alloy) and the low solubility of boron in molten Al were the major factors that contributed to the improvement in the corrosion resistance of B-doped samples.